|

Technology Of Industrial Popcorn Machine |

|||

|

Brand |

LYPC |

Quality |

High guarantee |

|

Price |

|

Technique |

Hot air popcorn machine |

|

Certification |

CE, ISO 9001 |

Main Material |

SUS 304 stainless steel |

|

Condition |

New |

Application |

Popcorn production |

|

Warranty Time |

1 year |

Type |

Automatic |

| Technology Of Industrial Popcorn Machine | |

| 1. Vibrating feeder | The corn to be blasted is placed in the weighing hopper of the vibrating feeder, and the feeding speed is adjusted by adjusting the frequency of the electromagnetic vibrator. The feeding speed is 80-120kg/h. The feeding is uniform and stable. |

| 2.High-temperature blasting furnace | It is a new generation of continuous corn blasting equipment, with continuous feeding and discharging, the blasting rate is 98%, automatic temperature control, stable work, simple operation, and material can be discharged after starting. |

| 3.Rotary peeling machine | The hard surface of the blasted corn granules passes through the tumbling of the raw material, and the hard is knocked down by beating, and the bottom is equipped with a device system for automatic waste recycling. |

| 4. Sugar spray system | Sugar tank – sugar spray tank – feeder – roller. The sugar sprayer adopts an advanced electromagnetic diaphragm pump for raw material output. The sugar spraying flow can be adjusted. The sprayed liquid is combined with the popcorn in a single drum. |

| 5.Drying equipment | Dry and dehydrate the popcorn to improve the taste of the product. According to the drying output, it is divided into multi-layer belt reciprocating ovens, which are divided into five-meter five-layer ovens, eight-meter five-layer ovens, and ten-meter five-layer ovens. The multi-layer reciprocating ovens have the characteristics of energy saving and small footprint. In terms of use, it can be divided into electric oven and gas heating oven. |

| 6. Cooling machine | The popcorn coming out of the drying box has a certain temperature, which is convenient for the packaging behind the product to quickly cool down the product. The raw materials are packaged in a timely manner according to the packaging bag conditions. |

|

Technology Of Industrial Popcorn Machine |

|||||

|

NO. |

ITEM |

PICTURE |

TECHNICAL PARAMETERS |

UNIT |

CHARACTERISTICS |

|

1 |

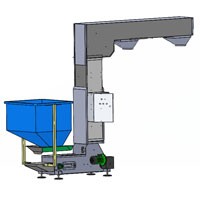

Corn Feeding Machine |

|

Function |

1 |

One Corn Feeding Machine with Two Feeding Hoppers, applied to Optic Sensor, high cost effective, and hidden circuit, safer and easier to clean. |

| Convey the raw corns into the hot air popcorn machine. | |||||

| Technical parameter | |||||

| Size: 3732*890*2650mm | |||||

|

2 |

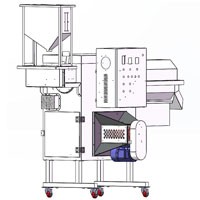

Hot Air Popcorn Machine |

|

Function |

2 |

Easy to adjust production capacity with Two Hot air Popcorn Machine, Besides, the most important part is this machine comes with cooling and filtering popcorn function, economizing on electricity. |

| Popping the raw corns into popcorn with hot air. | |||||

| Technical parameter | |||||

| Capacity: 60~90kg/h | |||||

| Size: 2190*1029*2135mm | |||||

|

3 |

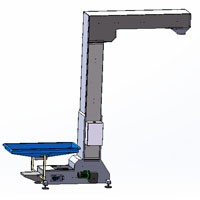

Popcorn Feeding Machine |

|

Function |

1 |

Hidden convey to protect popcorn from dust. Hidden circuit, safer and easier to clean. |

| Convey the popcorn into the popcorn feeding bin. | |||||

| Technical parameter | |||||

| Size: 4028*711*3800 mm | |||||

|

4 |

Pre-melting Tank |

|

Function |

2 |

Easy to inhale materials ( caramel, chocolate…) with Fully enclosed pre-melting tank, safter and health. |

| Melting the flavoring materials when the coating machine is working, such as chocolate, cheese, caramel, etc. | |||||

| Technical parameter | |||||

| Size: 1000*1000*2000mm | |||||

|

5 |

Active Feeding Bin |

|

Function |

1 |

Equipped with high quality and accurate senors on location, volume and so on. It could be lengthened according to your needs. |

| Through the sliding track, feeding the popcorn into the caramelizer. | |||||

| Technical parameter | |||||

| Size: 3000*1560*3030mm | |||||

|

6 |

Large Size Caramelizer |

|

Function |

2 |

Equipped with automatic kettle-dumping and self-clean system. Energy saving. |

| Coating different flavored popcorn with chocolate, cheese, caramel, etc. | |||||

| Technical parameter | |||||

| Size: 2659*900*2330mm | |||||

|

7 |

Z Type Elevator and Conveyor |

|

Function |

1 |

Easy to clean. Made of food grade SUS304 Stainless steel, healthier than plastic type. |

| Cooling and conveying the flavored popcorn into the cooling and separating machine. | |||||

| Technical parameter | |||||

| Size: 5462*1178*1505mm | |||||

|

8 |

Cooling and Separating Machine |

|

Function |

1 |

The rotating speed can be adjusted according to your needs. Easy to clean, high capacity. |