Complete SHAMPOO Plant consists of following equipments

- Wax Phase Vessel

- Water Phase Vessel

- Manufacturing Vessel

- Batch Storage Vessel

- Twin Lobe type product transfer Pump

- Positive displacement type Transfer Pump

- Vacuum Pump.

- Interconnecting pipe line

- Integrated PLC based control Panel

- Working Platform

A. Wax Phase Vessel

| Sr. no. | Description | Specifications |

| TAG | Wax Phase Vessel | |

| 01 | GENERAL SPECIFICATIONS | |

| A | Function | To prepare wax phase require for SHAMPOO manufacturing |

| B | Code | Built as per Good Engineering Practice and to comply cGMP standard |

| C | MOC | SS 316 contact parts and SS 304 non contact parts. Heavy parts and structures shall be cladded with SS 304 materials. |

| D | Type | Cylindrical Vertical with welded bottom dish and top dish. Vacuum compatible. |

| E | Mounting | Vertical on Legs with load cell |

| 02 | PROCESS DETAILS & OPERATIONAL DATA | |

| A | Operation Type | Batch |

| B | Fluid Handled in vessel | Client to confirm |

| C | Specific Gravity | 0.9 gms /cc |

| D | Fluid Handled in Jacket | Steam / Hot Water / Raw water |

| E | Service | Mixing |

| F | Operating Temperature | 20-80 deg. C |

| G | Operating Pressure | FV – ATM |

| H | Operating pressure in Jacket | 3.0 Kgs/cm2 |

| I | Minimum Steerable Volume | 20 % of gross Volume |

| J | Min. Temperature sensing Volume | 20% of working Volume |

| 03 | MATERIAL OF CONSTRUCTION | |

| A | Shell / Bottom / Top dish | SA 240 Gr. 316 |

| B | Jacket | SA 240 Gr. 304 |

| C | Stirrer Mounting Pad | SA 240 Gr. 316 |

| D | Stirrer Shaft | SS 316 |

| E | Gasket | Food grade Silicon |

| F | Nozzles | SS 316, Seamless pipes |

| G | Mechanical Seal Type | Double Cartridge water cooled type |

| H | Baffles | SS 316 |

| I | Monkey Ladder | SS 316 |

| J | Legs Pipe | SS 304 |

| K | Base plate | SS 304, suitable for load cell mounting |

| L | Hardware – Internal | SS 316 |

| M | Hardware – external | SS 304 |

| N | Product outlet Valve type / MOC | Sanitary Design with 1 side flange an 1 side TC connection / SS 316 |

| 04 | INSULATION AND CLADDING | |

| A | Type of insulation | Mineral wool |

| B | Insulation Thickness | 50 mm |

| C | Insulation cladding | SS 304, full welded |

| 05 | DRIVE AND AGITATOR DATA | |

| A | Type of agitator | Rotor Stator type homogenizer |

| B | Agitator Entry | Top Entry. |

| C | No. of Impeller | 01 |

| D | Impeller Dia | As per design |

| E | Shaft Dia. | As per design |

| G | Shaft Type | Solid |

| H | RPM | 1440 RPM |

| I | No. of Baffles | 01 No. |

| J | Motor Type | TEFC/Non FLP / 3Ph/415V/AC |

| K | Transmission | Direct Mounting |

| 06 | SURFACE FINISH | |

| A | Product Contact Parts | 220 grit mirror finish. Surface roughness |

B. Water Phase Vessel

| Sr. no. | Description | Specifications |

| TAG | Water Phase Vessel | |

| 01 | GENERAL SPECIFICATIONS | |

| A | Function | To prepare water phase require for SHAMPOO manufacturing |

| B | Code | Built as per Good Engineering Practice and to comply cGMP standard |

| C | MOC | SS 316 contact parts and SS 304 non contact parts. Heavy parts and structures shall be cladded with SS 304 materials. |

| D | Type | Cylindrical Vertical with welded bottom dish and top dish. Vacuum compatible. |

| E | Mounting | Vertical on Legs with load cell |

| 02 | PROCESS DETAILS & OPERATIONAL DATA | |

| A | Operation Type | Batch |

| B | Fluid Handled in vessel | Client to confirm |

| C | Specific Gravity | 0.9 gms /cc |

| D | Fluid Handled in Jacket | Steam / Hot Water / Raw water |

| E | Service | Mixing |

| F | Operating Temperature | 20-80 deg. C |

| G | Operating Pressure | FV – ATM |

| H | Operating pressure in Jacket | 3.0 Kgs/cm2 |

| I | Minimum Steerable Volume | 20 % of gross Volume |

| J | Min. Temperature sensing Volume | 20% of working Volume |

| 03 | MATERIAL OF CONSTRUCTION | |

| A | Shell / Bottom / Top dish | SA 240 Gr. 316 |

| B | Jacket | SA 240 Gr. 304 |

| C | Stirrer Mounting Pad | SA 240 Gr. 316 |

| D | Stirrer Shaft | SS 316 |

| E | Gasket | Food grade Silicon |

| F | Nozzles | SS 316, Seamless pipes |

| G | Mechanical Seal Type | Double Cartridge water cooled |

| H | Baffles | SS 316 |

| I | Monkey Ladder | SS 316 |

| J | Legs Pipe | SS 304 |

| K | Base plate | SS 304, suitable for load cell mounting |

| L | Hardware – Internal | SS 316 |

| M | Hardware – external | SS 304 |

| N | Product outlet Valve type / MOC | Sanitary Design with 1 side flange an 1 side TC connection / SS 316 |

| 04 | INSULATION AND CLADDING | |

| A | Type of insulation | Mineral wool |

| B | Insulation Thickness | 50 mm |

| C | Insulation cladding | SS 304, full welded |

| 05 | DRIVE AND AGITATOR DATA | |

| A | Type of agitator | Propeller type |

| B | Agitator Entry | Top Entry. |

| C | No. of Impeller | 01 |

| D | Impeller Dia | As per design |

| E | Shaft Dia. | As per design |

| G | Shaft Type | Solid |

| H | RPM | 1440 RPM |

| I | No. of Baffles | 01 No. |

| J | Motor Type | TEFC/Non FLP / 3Ph/415V/AC |

| K | Transmission | Direct Mounting |

| 06 | SURFACE FINISH | |

| A | Product Contact Parts | 220 grit mirror finish. Surface roughness |

C. Manufacturing Vessel

| Sr. no. | Description | Specifications |

| TAG | SHAMPOO Manufacturing Vessel | |

| 01 | GENERAL SPECIFICATIONS | |

| A | Function | To prepare SHAMPOO |

| B | Code | Built as per Good Engineering Practice and to comply cGMP standard |

| C | MOC | SS 316 contact parts and SS 304 non contact parts. Heavy parts and structures shall be cladded with SS 304 materials. |

| D | Type | Cylindrical Vertical with welded bottom dish and flanged top dish. Hydraulic Lifting of top drive assembly. Max. Lift will be 500 mm OR according to site condition. |

| E | Mounting | Vertical on Legs with (Optional) load cell mounting |

| 02 | PROCESS DETAILS & OPERATIONAL DATA | |

| A | Operation Type | Batch |

| B | Fluid Handled in vessel | SHAMPOO |

| C | Specific Gravity | 0.9 gms/cc |

| D | Fluid Handled in Jacket | Steam / Hot Water / Raw water |

| E | Service | Preparation of SHAMPOO |

| F | Operating Temperature | 10 to 90 Deg. C |

| G | Operating Pressure | FV to ATM |

| H | Operating pressure in Jacket | 3.5 Kgs/cm2 |

| I | Minimum Steerable Volume | 20 % of gross Volume |

| J | Min. Temperature sensing Volume | 20% of working Volume |

| 03 | MATERIAL OF CONSTRUCTION | |

| A | Shell / Bottom / Top dish | SA 240 Gr. 316 |

| B | Jacket | SA 240 Gr. 304 |

| C | Agitator Mounting Pad | SA 240 Gr. 304 with SS 316 bushing |

| D | Agitator Shaft | SS 316 |

| E | Gasket | Food grade Silicon |

| F | Nozzles | SS 316, Seamless pipe, Sch. 40 |

| G | Mechanical Seal Type | Single Dry Mechanical seal – Hi-Fab or Leak Proof make. |

| H | Baffles | SS 316 |

| I | Monkey Ladder | N/A |

| J | Legs Pipe | SS 304 |

| K | Base plate | SS 304 |

| L | Hardware – Internal | SS 316 |

| M | Hardware – external | SS 304 |

| N | Product outlet Valve type / MOC | Sanitary Design with 1 side flange an 1 side TC connection / SS 316 |

| 04 | INSULATION AND CLADDING | |

| A | Type of insulation | Mineral wool |

| B | Insulation Thickness | 50 mm |

| C | Insulation cladding | SS 304, full welded |

| 05 | DRIVE AND AGITATOR DATA | |

| A | Type of agitator | Semi Contra Type with bottom entry homogenizer. OR Semi Contra Type Inline Homogenizer |

| B | Agitator Entry | Top Entry for Semi Contra & bottom entry for Homogenizer. |

| C | No. of Agitator | 01 |

| D | Agitator Design | As per design |

| E | Shaft Type | Solid |

| G | RPM | 10- 40 for Semi Contra Agitator ( Variable through VFD) & 2800 for Homogenizer |

| H | No. of Fix Baffles | As per design |

| I | Motor Type | TEFC/Non FLP / 3Ph/415V/AC / IE 3 |

| J | Transmission | Rigid Coupling for shaft joint inside the vessel and Flexible coupling for gear box – agitator shaft. Motor to Gear Box – direct couple |

| K | Direct couple for homogenizer motor | |

| L | Transmission | Rigid Coupling for shaft joint inside the vessel and Flexible coupling for gear box – agitator shaft. Motor to Gear Box – direct couple |

| M | Gear Box for Main Drive | Worm reduction / Heli Bevel type |

| N | Bearing Housing | CI / MS Bearing housing with heavy duty Taper roller bearings – 02 nos. Covered with SS 304 cover. |

| O | Drive Stool assembly | MS / CI stool with 20 thick Flanges, covered with SS 304 cover. |

| P | Agitator PAD Plate | Solid SS 304 with SS 316 bushing |

| Q | Scrapper Blades | 02 Nos. Floating type PTFE scrapper blades shall be provided to cover total wall surfaces of the mixing vessel. |

| R | TOP Dish Lifting | By means of 02 nos. hydraulic cylinders and power pack unit. |

| S | Host Burst check valve | Will Be provided which will not allow the lifted load to come down in case the hydraulic hose pipe burst or any leakages from hose pipe / joint. |

| T | Scrapper Blades | 02 Nos. Floating type PTFE scrapper blades shall be provided to cover total wall surfaces of the mixing vessel. |

| 06 | SURFACE FINISH | |

| A | Product Contact Parts | 220 grit mirror finish. Surface roughness |

D. Batch Storage vessel without jacket

| Sr. No. | Description | Specifications |

| 1. | GENRAL DESCRIPTION | |

| A | Function | Storage of SHAMPOO . |

| B | Code | Built as per Good Engineering Practice and to comply cGMP |

| C | MOC | SS 316 contact parts and SS 304 non contact parts. Heavy parts and structures shall be cladded with SS 304 materials. |

| D | Description | Vertical, cylindrical with conical bottom Loose Top Lid. Leg Supported Without any jacket & agitator |

| E | Vessel Type | Cylindrical vertical with Conical bottom & Loose top Lid. |

| 2. | Process and Operation Data | |

| A | Fluid Handled in Vessel | SHAMPOO |

| B | Service | SHAMPOO Storage |

| C | Design Temp. | 100 Deg. C |

| D | Operating Temp. | AMB |

| E | Operating Pressure of Vessel | ATM + Static |

| F | Operating Type | Batch |

| SURFACE FINISH | ||

| A | Internal Finish | Mirror 240 Grit. Surface roughness |

E. INTER CONENCTING PIPE LINES

Inter connecting pipe line provided as under;

- From wax phase vessel to manufacturing vessel through inline type conical filter

- From water phase vessel to manufacturing vessel through inline type conical filter

- From Manufacturing Vessel’s outlet to recirculation nozzle through Lobe Pump

- From manufacturing vessel to batch storage vessel through lobe pump.

- From Batch storage vessel to inlet of positive displacement type plunger pump inlet.

- From plunger pump to filling machine hopper ( Max. length 3 Mtrs. With 2 bend)

All interconnecting pipe lines are internally electro polished and with TC joints for easy in cleaning.

F. WORKING PLATFORM

SS 304 working platform manufactured out of SS pipes and Angles. Platform top shall be of 18 swg dimpled plate. SS 304 pipe railing as a safety railing shall be provided for safe working of operator.

Platform shall be suitable to cover wax phase, water phase and manufacturing vessels & Storage Vessel. Operating panel shall be mounted on the working platform at suitable location.

G. TWIN LOBE TYPE TRANSFER PUMP

- PUMP TYPE : TWIN lobe

- MODEL : Sanitary Design, GMP Model

- Contact Parts : SS 316

- Mounting : On Trolley with wheels.

H. POSITIVE DISPLACEMENT TYPE TRANSER PUMP

- PUMP TYPE : Positive Displacement Plunger type

- MODEL : Sanitary Design, GMP Model

- Contact Parts : SS 316

- Mounting : On Trolley with wheels.

I. WATER RING TYPE VACUUM PUMP

- PUMP TYPE : Water Ring type

- Model : Standard

- MOC : C. I.

- Mounting : On SKID

5. INTEGRATED CONTROL PANEL

Mild Steel powder coated PLC based power panel, which shall be mounted on service floor consisting of require switch gears and fuses, with SS 304 colour touch HMI based Operating panel mounted near the equipment inside the production area, consisting of following controls

- Main Drive motor ON OFF for wax phase vessel with motor ON indication.

- DTIC for wax phase vessel

- Main Drive motor ON OFF for water phase vessel with motor ON indication.

- DTIC for water phase vessel.

- Main Drive motor ON-OFF for manufacturing vessel with motor ON indication.

- POT for RPM variation for semi contra agitator.

- Main drives ON-OFF for homogenizer motor with motor ON indication.

- Timer for homogenizer motor.

- Vacuum pump ON OFF.

- Twin Lobe pump ON OFF.

- Positive displacement transfer pump ON OFF

- Steam ON-OFF selector switch for all jacketed vessels.

- Total process timer for Semi Contra agitator.

- Actual weight display for wax phae, water phase and main mixer.

SAFETY FEATURES

- Water flow sensor for mechanical seal of In Line homogenizer.

- Single phase preventer.

- Over Load relay for motor overloading protection.

- Heat Extraction fan and ventilation filter in power panel.

- Emergency OFF in operating panel.

Note : Cable between power panel to control panel and from power panel to respective motors are not in our scope of supply.

| 01 | GENERAL POINTS | ||

| A | All product contact parts shall be of SS 316 & non-contact parts shall be of SS 304, unless otherwise specified. | ||

| B | All electrical shall be of non FLP construction. | ||

| C | All electrical switch gears shall be of C&S / L&T / Siemens make | ||

| 02 | DOCUMENTS | ||

| A | FDS | Provided immediate up on receipt of order | |

| B | DQ | Provided immediate up on receipt of order | |

| C | Drawing for approval | Provided immediate up on receipt of order | |

| D | Final As built Drawing | Provided along with machine dispatch | |

| E | IQ / OQ / PQ | Provided along with machine dispatch | |

| F | O&M Manual | Provided along with machine dispatch | |

| G | MTR | Provided along with machine dispatch | |

| H | RM test certificates | Provided along with machine dispatch | |

| I | Bought out items test certificates | Provided along with machine dispatch | |

| J | Electrical Diagram | Provided along with machine dispatch | |

| K | Internal Trial report | Provided along with machine dispatch | |

| L | Warrantee Certificate | Provided along with machine dispatch | In our format |

| M | FAT file / report | Provided before FAT | |

| N | SAT file / report | Provided along with machine dispatch | |

Batch Size

- Available model 20 KG to 10,000KG working Capacity.

- Working capacity is customized as per customer’s requirement. APPLEPACK can provide more than 10,000kgs capacity model also.

A. Shampoo is a hair care product that is used for removal of oils, dirt, dandruff, environmental pollutant & other contaminant particles that gradually built up in hairs.

B. Shampoo is a clear / opaque viscous liquid.

C. Normal Viscosity of Shampoo is in the range of 500 – 1500 centipoise.

D. It contains approx… 20 – 40 % solids & Ph value is around 5.0 to 5.5

E. Classifications of Shampoo

a. Based on use or functions,

- Conditioning shampoo

- Antidandruff or Therapeutic Shampoo

- Baby Shampoo

- Balancing Shampoo

- Clarifying Shampoo

b. Based on appearance

- Cream Shampoo

- Oil Shampoo

- Medicated Shampoo

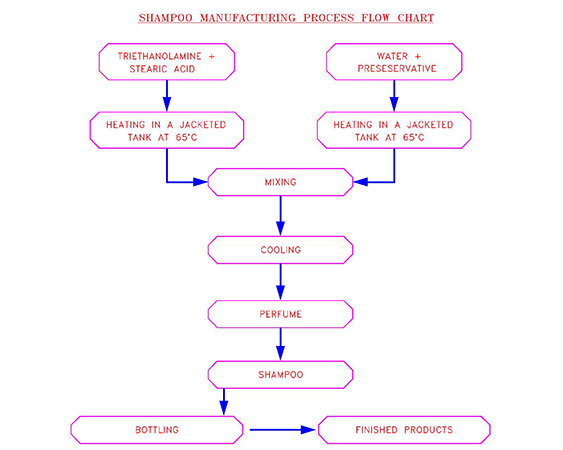

F. General Manufacturing process flow diagram is

G. Shampoo Manufacturing Plant consists of

- Base / Phase preparation Mixer/s

- Shampoo Mixer

- Storage Vessel

- Transfer pumps

- Working platform

- Integrated control Panel

H. SALIENT FEATURES

- Capacities available from lab scale 50 ltrs. To 10000 Ltr / batch

- Good Engineering Practice follows for manufacturing.

- Stainless Steel 316 / 316 L grade wetted parts and Stainless Steel 304 or mild steel painted non-wetted parts.

- Variable speed of agitator to suit different process conditions.

- Different heating modes like steam, electrical, Thermic Oil , Hot water

- Electrical control panel with require controls and safety interlocks.

- Disperser blade agitator for phase vessel and Pitch Blade Turbine type agitator for Shampoo Mixer.

I. OPTIONALS

- Fully automatic operation with PLC + HMI panel.

- All valves will be pneumatically operated.

- Utility control accessories for mixer and phase vessel

- Load cell for weight measurement.

- Data logger with printer facility

- SCADA connectivity

- Tailor made construction

J. GENERAL LAYOUT

K. TECHNICAL SPECIFICATIONS

| BATCH CAPACITY IN LTR. | PHASE VESSEL WORKIIG VOLUME IN LTR. | MIXER VOLUME IN LTR. | TOTAL CONNECTED POWER LOAD | SPACE REQUIRE IN MM. | |||

| LENGTH | WIDTH | HEIGHT | |||||

| 50 | 35 | 50 | 3.75 HP | ||||

| 100 | 70 | 100 | 4.0 HP | ||||

| 250 | 175 | 250 | 7.5 HP | ||||

| 500 | 350 | 500 | 10.0 HP | ||||

| 1000 | 700 | 1000 | 16.0 HP | ||||

| 1500 | 1050 | 1500 | 20.5 HP | ||||

| 2000 | 1400 | 2000 | 25.5 HP | ||||

| 3000 | 2100 | 3000 | 28.0 HP | ||||

| 5000 | 3500 | 5000 | 42.5 HP | ||||

| 10000 | 7000 | 10000 | 57.5 HP | ||||

Shampoo Manufacturing plant – Shampoo Mixer machines and equipment

Shampoo manufacturing plant is best suitable for different kind of shampoo like Clarifying shampoo , Everyday shampoo , Volumizing shampoo , Oily hair shampoo , Normal hair shampoo , Dry, damaged hair shampoo , Colored hair shampoo ,2-in-1 shampoo Medicated shampoo , Swimmer’s shampoo etc

- Shampoo is a hair care product that is used for removal of oils, dirt, dandruff, environmental pollutant & other contaminant particles that gradually built up in hairs.

- Shampoo is a clear / opaque viscous liquid.

- Normal Viscosity of Shampoo is in the range of 500 – 1500 centipoise.

- It contains approx… 20 – 40 % solids & Ph value is around 5.0 to 5.5

- Classifications of Shampoo

- Based on use or functions,

- Conditioning shampoo

- Antidandruff or Therapeutic Shampoo

- Based on use or functions,

- Baby Shampoo

- Balancing Shampoo

- Clarifying Shampoo

- Based on appearance

- Cream Shampoo

- Oil Shampoo

- Medicated Shampoo

- General Manufacturing process flow diagram is

- Shampoo Manufacturing Plant consists of

- Base / Phase preparation Mixer/s

- Shampoo Mixer

- Storage Vessel

- Transfer pumps

- Working platform

- Integrated control Panel

- SALIENT FEATURES

- Capacities available from lab scale 50 ltrs. To 10000 Ltr / batch

- Good Engineering Practice follows for manufacturing.

- Stainless Steel 316 / 316 L grade wetted parts and Stainless Steel 304 or mild steel painted non-wetted parts.

- Variable speed of agitator to suit different process conditions.

- Different heating modes like steam, electrical, Thermic Oil , Hot water

- Electrical control panel with require controls and safety interlocks.

- Disperser blade agitator for phase vessel and Pitch Blade Turbine type agitator for Shampoo Mixer.

- OPTIONALS

- Fully automatic operation with PLC + HMI panel.

- All valves will be pneumatically operated.

- Utility control accessories for mixer and phase vessel

- Load cell for weight measurement.

- Data logger with printer facility

- SCADA connectivity

- Tailor made construction

Shampoo /Lotion / Petroleum Jelly Manufacturing Plant

Apple Pack process Equipment offering shampoo product manufacturing plant and mixer equipment / machine to make different kind of shampoo , Ayurveda , Herbal etc , we offering below our shampoo making equipment.

- Clarifying shampoo Manufacturing plant and Mixer machines and equipment

- Everyday shampoo Manufacturing plant and Mixer

- Volumizing shampoo Manufacturing plant and Mixer

- Oily hair shampoo Manufacturing plant and Mixer

- Normal hair shampoo Manufacturing plant and Mixer

- Dry, damaged hair shampoo Manufacturing plant and Mixer

- Colored hair shampoo Manufacturing plant and Mixer

- 2-in-1 shampoo Manufacturing plant and Mixer

- Medicated shampoo Manufacturing plant and Mixer

- Swimmer’s shampoo Manufacturing plant and Mixer

- GENERAL LAYOUT

- TECHNICAL SPECIFICATIONS OF SHAMPOO MANUFACTURING PLANT & SHAMPOO MIXER

| BATCH CAPACITY IN LTR. | PHASE VESSEL WORKIIG VOLUME IN LTR. | MIXER VOLUME IN LTR. | TOTAL CONNECTED POWER LOAD | SPACE REQUIRE IN MM. | ||

| LENGTH | WIDTH | HEIGHT | ||||

| 50 | 35 | 50 | 3.75 HP | |||

| 100 | 70 | 100 | 4.0 HP | |||

| 250 | 175 | 250 | 7.5 HP | |||

| 500 | 350 | 500 | 10.0 HP | |||

| 1000 | 700 | 1000 | 16.0 HP | |||

| 1500 | 1050 | 1500 | 20.5 HP | |||

| 2000 | 1400 | 2000 | 25.5 HP | |||

| 3000 | 2100 | 3000 | 28.0 HP | |||

| 5000 | 3500 | 5000 | 42.5 HP | |||

| 10000 | 7000 | 10000 | 57.5 HP | |||

Note : Space requirement will be intimated you soon.

Our cosmetics emulsifier vessels is built to processing and store cosmetic, baby product, liquid soaps, body wash, lotion, conditioners, mouthwash, shampoos, hair gels, and other personal care product.

Mixer with emulsifying systems to produce all kind of dispersions for the pharmaceuticals and cosmetic industry, including ointment, cream and gel, syrup, paste and lotion, beauty product, and hair care treatment.

Cosmetic Blender , Shampoo Liquid Soap Mixer Machine , Agitator – Thailand Shampoo Mixing Tank

Production line for gels, shampoo and creams – Applepack

Cream Manufacturing Plant – shampoo mixer equipment Germany

Our batch mixer are specialized for mixing shampoo and conditioners with:

- Naturals oil-based and herbal formulations

- Standards or 2-in-1 formulation

- Anti-dandruffs shampoo formulation

- UV protective ingredient

- Babie and kid shampoo formulation

- Antibacterial or medicated shampoo formulas

Shampoo Manufacturing & Making Process

How to Produce Shampoo with Our Mixing Equipment’s

A Shampoo is a preparations of a surfactants (i.e. surface active material) in either a liquids, solids or powder form. It contains varying amounts of conditioning agents and many other ingredients in an aqueous base. When used on the hair, it will remove surface grease, dirt, and skin debris from the hair shaft and scalp.

Shampoo, Conditioner & Hand cream Manufacturing Process of Manufacturing the best equipment for your production.

Read on to know how to manufacture shampoo.

Shampoo Formulation

Baby shampoo formulations usually have mild fragrance containing a small percentage of natural oils. In contrast, men’s shampoos contain special dandruff-free ingredients and a masculine aroma. For women, common marketing for shampoos may be having hair-smoothening and hair-moisturizing features. They may also include natural glow and enhanced fragrance. Even pets have specialized shampoos for grooming.

Here’s a typical shampoo formulation:

| Ingredient Type | Examples | Percentage | Function |

| Deionized Water | 73-90% | Main ingredient of many shampoos and cosmetics as the main solvent | |

| Primary Surfactant | Sodium/Ammonium Lauryl sulfates | 8-15% active | Main component of shampoo, Foaming and detergency purposes; typically anionic surfactants |

| Secondary Surfactant | Cocamidopropy l Betaine, Coco Betaine, Lauryl/Coco Hydroxypropyl Sultaine, Disodium Cocoamphoacetate, Cocamide MEA, and Deacyl Glucoside. | 2-6% active | Boosts foam formation; improve detergency, mildness and hair condition; function by forming mixed micelles with anionic primary surfactants in which shampoo is thickened and mildness is induced. |

| Thickening polymers | Stearic ethanol amide | 0-2% | Increases viscosity of solution |

| Salt 0-2% | 0-2% | Thickens solution by reducing micelle charge density, helping to promote the conversion of spherical- to rod-shaped micelles, which can entangle and cause increased viscosity | |

| Opacifying Pearling Agents | Alkanolamides of higher fatty acids, propylene glycol, Mg, Ca and Zn salts of stearic acid, spermaceti, etc | 0-1% active | Substances that make shampoo more light and impenetrable by radiation |

| Chelating agent | EDTA or ethylenediaminetetraacetic acid | 0.05-.2% | Agent for improving hard water flowability and performance |

| Conditioning emollients | Typically Silicone or other minerals such as Lanolin, mineral oil, herbal extracts, egg derivatives | 0-1% | Added to shampoo to offset the harsh effect of surfactants on hair and fabric; improves and promotes hair softness, smoothness and reduces static charge to make hair less friskier. |

| Conditioning polymers | Guar Hydroxypropyltrimonium Chloride (the most popular), Polyquaternium 10, Polyquaternium 6, and Polyquaternium 7 | 0-1% | Anti-static, wet/dry conditioning |

| Fragrance | 0-.5% | Combinations of natural and/or man-made substances that are added to the shampoo that gives a specific smell appealing to the consumer | |

| Preservatives | Methyl and propyl paraben, formaldehyde | 0.001-1% | Prolongs the shelf-life of shampoo. |

The Mixing Process of Shampoo

Following the shampoo formulation procedure, a typical manufacturing process would be as follows:

- Water is introduced into the process vessel and is heated to 130-140˚F (55-60˚C) to aid dilution/hydration of other ingredients.

- The primary and secondary surfactants are added to the water together with the other ingredients such as the thickening polymers and others. At this stage, the dilution of the surfactant will be more difficult.

- Conditioners and other ingredients are added.

- Next, the pH of the solution can be adjusted to the required level.

- Salt is added.

- Lastly, color and fragrance are added.

Shampoo Mixing Issues

A number of problems can be encountered when using conventional agitators:

- As with other cosmetic manufacturing problems in mixing, aeration is always encountered. Aeration can lead to the murking of clear shampoos and can present a problem in the shampoo filling machine.

- Conditioning emollients such as silicones are immiscible with water and can be chemically incompatible with some surfactants. This makes it a lot more difficult to emulsify or suspend the solution.

- Insufficient shear can also prevent silicones from being reduced to its finest possible size.

- Globules can be formed when the agitator does not perform with high shear as many ingredients have a much higher viscosity than water. These globules may simply be washed around without being diluted/dispersed.

- Thickening agents such as carbomers, and cellulose or gum based products may require high shear mixing to be activated.

- The addition of sodium chloride becomes increasingly difficult as the viscosity rises.