As a professional Automatic wafer biscuit production line manufacturer, Full-automatic wafer production line features reliable performance, compact structure, small occupation,high yield,lower energy consumption,convenient maintenance, simple operation. The driven motors adopt SEW Germany, the bearings use SKF. Operating system uses PLC programing to make the process automated and easy control.

Wafer biscuits making machine adopting hearing-medium conduction technology with heating oil as medium, the plant is a new generation product developed exclusively in China based on the advanced structure of existing plants from domestic market and abroad. If offers an ideal solution for lower power consumption and overall production cost,and keeping the same surface color for all biscuits. The plant mainly consists of mixing system,automatic feeding system, tunnel-type oven, sheet feeding and cooling device, coating machine, cutter and organic heating medium boiler, etc. With compact structure and unique reliability, the plant is one of the most preferred equipment in foodstuff industry.

WHATS THE PROCESS OF WAFER BISCUITS MAKING MACHINE?

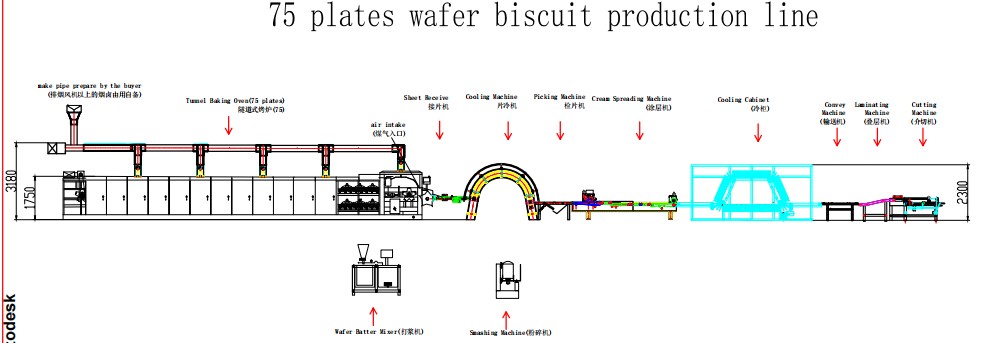

Batter Mixing — Wafer sheet baking — Wafer Sheet Cooling — Wafer sheet cream coating — Wafer sheet cooling — Wafer biscuits cutting

Wafer sheet baking from oven, automatically transfer to cooling tower and cooling in the air. Cream will be automatically applied on wafer sheet, after the cooling from cooling cabinet, wafer book cut on cutting machine.

WHATS THE CAPACITY LIST OF WAFER BISCUITS MAKING MACHINE?

| CAPACITY LIST OF WAFER BISCUITS MAKING MACHINE | |||||||

| Electricity Wafer Production Line | |||||||

| Type | 27 | 33 | 39 | 45 | 51 | 63 | 75 |

| Electricity | 120KW | 140KW | 160KW | 180KW | 200KW | 240KW | 260KW |

| Capacity | 100KG/H | 125KG/H | 150KG/H | 175KG/H | 200KG/H | 250KG/H | 300KG/H |

| Gas Wafer Production Line | |||||||

| Type | 27 | 33 | 39 | 45 | 51 | 63 | 75 |

| Gas | 13KG/H | 15KG/H | 19KG/H | 23KG/H | 27KG/H | 32KG/H | 37KG/H |

| Capacity | 100KG/H | 125KG/H | 150KG/H | 175KG/H | 200KG/H | 250KG/H | 300KG/H |

WHATS THE FEATURES AND CHARACTERISTICS OF WAFER BISCUITS MAKING MACHINE?

1.All motor, electrical equipments are international standard—famous international brand or Chinese brand.

2.Reasonable layout, compact structure, small occupation.

3.High automatic, stable performance,machine can be controlled separately, simple operation and easy maintenance.

4.Elements of wafer machine uses famous international or imported brand: motors from SEW Germany and bearings are high temperature prevent SKF Germany. HMI operation panel and PLC unit can be Mitsubishi or Siemens. Appliances adopts Danfoss, Schnerider, Omron. Conveyor belt is foodstuff PU quality.

WHATS THE TECHNICAL PARAMETERS OF WAFER BISCUITS MAKING MACHINE?

| TECHNICAL PARAMETERS OF WAFER BISCUITS MAKING MACHINE | ||

| Item | Description | Parameters |

| 1 | Output | 2.5–7.5 tons/24 hours |

| 2 | Total power | 55.44 kw (380V 50Hz) |

| 3 | Rate of finished product | More than 98% |

| 4 | Gas supply pressure | 0.15-0.2 Mpa |

| 5 | Air compression value | 0.9M3/Min/0.8Mpa |

| 6 | Baking plate size | 470mm×325mm~500mm×350mm |

| 7 | Effective cutting size | 455mm×315mm~485mm×340mm |

| 8 | Worker | 4 person ( excluding packing workers) |